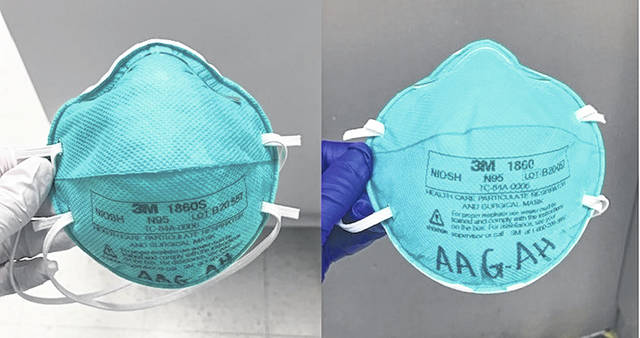

CHILLICOTHE – Adena Health System is successfully managing its inventory of N95 masks for front line caregivers by partnering with Battelle Institute through its new decontamination system. Adena was among some of the first in the nation to collaborate with Battelle in its process to decontaminate N95 or N95-equivalent respirators for reuse by health care personnel during the COVID-19 pandemic.

“The national shortage of personal protective equipment (PPE) for front line caregivers has kept the health care industry, including Adena, looking for ways to make our inventories last as long as possible,” said Adena President and CEO Jeff Graham. “While Adena was in good shape for our day-to-day PPE needs, when facing a pandemic, we had to get more in house and have been purchasing what we can when it is available. However, learning that Battelle was working on a process to decontaminate N95s in mass quantities was a game changer. Adena was fortunate to get in on the ground floor of this exciting process. We are grateful to now have extended the longevity of this important equipment that helps to keep our front line heroes safe and healthy.”

Battelle received emergency use authorization by the Food and Drug Administration (FDA) for its process on March 29, 2020. Days later, Adena sent its first batch of 33 N95 masks to Battelle for decontamination and recycling. Thirty-two of Adena’s first N95 respirators came back in like-new condition, and were placed back into the System’s PPE inventory.

“It only takes Battelle 24 hours to turn around for us, and they check each mask before sending it back,” said Adena Sterile Processing Manager Sidney Brintlinger. “As of April 17, we have sent out 361 masks, with nearly all coming back to us, clean and ready for their next use should we run out of new N95s during the pandemic.”

According to Battelle, successful testing on decontaminated N95 respirators demonstrated acceptable performance through 20 decontamination cycles. Prior to submission, Adena’s Sterile Processing staff inspects each respirator, discarding those with visible soiling or damage, and N95s that are cellulose-based, which are incompatible with Battelle’s decontamination process.

For the most up to date COVID-19 specific information, and updates related to Adena operations and services, please visit adena.org/COVID19 ; also follow Adena on Facebook, Instagram, or Twitter @adenamedical.